Carbon fiber, a lightweight and high-strength material, has gained significant attention in recent years for its diverse applications in various industries, including aerospace, automotive, sports equipment, and renewable energy. The carbon fiber industry has been witnessing rapid growth, driven by technological advancements, increasing demand for lightweight materials, and growing environmental concerns. Let's take a closer look at the latest market trends and developments in the carbon fiber industry.

Carbon fiber, a lightweight and high-strength material, has gained significant attention in recent years for its diverse applications in various industries, including aerospace, automotive, sports equipment, and renewable energy. The carbon fiber industry has been witnessing rapid growth, driven by technological advancements, increasing demand for lightweight materials, and growing environmental concerns. Let's take a closer look at the latest market trends and developments in the carbon fiber industry.

Carbon fiber, a lightweight and high-strength material, has gained significant attention in recent years for its diverse applications in various industries, including aerospace, automotive, sports equipment, and renewable energy. The carbon fiber industry has been witnessing rapid growth, driven by technological advancements, increasing demand for lightweight materials, and growing environmental concerns. Let's take a closer look at the latest market trends and developments in the carbon fiber industry.

In addition to aerospace and automotive, the sports and leisure industry is also a significant consumer of carbon fiber. Carbon fiber composites are used in sports equipment, such as tennis rackets, golf clubs, bicycles, and fishing rods, due to their lightweight and high-strength properties. As the demand for high-performance sports equipment continues to rise, the demand for carbon fiber in the sports and leisure industry is expected to grow. Moreover, the increasing awareness about health and fitness among the global population has led to a growing demand for sports and leisure activities, further driving the demand for carbon fiber in this sector.

Renewable energy is another emerging application of carbon fiber. Carbon fiber composites are used in wind turbine blades, as they provide high strength, stiffness, and fatigue resistance, making them ideal for the harsh operating conditions of wind turbines. With the increasing focus on renewable energy sources and the growing installation of wind farms worldwide, the demand for carbon fiber in the renewable energy sector is expected to grow significantly. According to a report by Research and Markets, the global carbon fiber in renewable energy market is projected to reach USD 4.7 billion by 2025, growing at a CAGR of 10.8% from 2020 to 2025.

Furthermore, advancements in carbon fiber manufacturing technology have been driving the growth of the industry. Traditional methods of carbon fiber production, such as the polyacrylonitrile (PAN) process, are expensive and energy-intensive. However, new manufacturing processes, such as the low-cost precursor-based processes and the lignin-based processes, have emerged, which offer cost-effective and sustainable options for carbon fiber production. These advancements are expected to boost the production capacity of carbon fiber, making it more accessible and affordable for various applications.

Despite the promising growth prospects, the carbon fiber industry also faces challenges. The high cost of carbon fiber production, especially for high-performance fibers, remains a significant barrier to widespread adoption in some industries. The complex and energy-intensive manufacturing process, as well as the limited availability of raw materials, also contribute to the high cost of carbon fiber. However, with the advancements in manufacturing technology and the increasing demand for carbon fiber, there are efforts being made to develop more cost-effective production methods and explore alternative raw materials.

Another challenge for the carbon fiber industry is the environmental impact. The production of carbon fiber involves the use of chemicals, energy, and high-temperature processes, which can result in carbon emissions and environmental pollution. Additionally, the disposal of carbon fiber waste and end-of-life products can also pose environmental challenges. However, there are ongoing efforts to develop more sustainable and environmentally friendly production processes, such as recycling of carbon fiber waste and using bio-based precursors.

In terms of market trends, there is a growing focus on lightweight materials and sustainability across various industries, which is driving the demand for carbon fiber. The increasing adoption of electric and hybrid vehicles, the demand for fuel-efficient aircraft, and the growing interest in renewable energy sources are all contributing to the demand for carbon fiber. Additionally, there is a rising trend of using carbon fiber in consumer goods, such as sports equipment, luxury goods, and electronics, due to its lightweight and high-performance properties.

In recent years, there have been significant investments and collaborations in the carbon fiber industry. Many companies are investing in research and development to innovate and develop new products with enhanced performance and lower costs. Additionally, collaborations between companies, research institutions, and governments are aimed at accelerating the growth of the carbon fiber industry through joint research, development of standards, and funding support.

In conclusion, the carbon fiber industry is experiencing rapid growth driven by increasing demand from aerospace, automotive, sports and leisure, and renewable energy sectors. Advancements in manufacturing technology and efforts towards sustainability are expected to further drive the growth of the industry. However, challenges related to cost, environmental impact, and disposal of waste remain, and continuous innovation and collaboration will be crucial in addressing these challenges and ensuring the sustainable growth of the carbon fiber industry in the future.

Krosino Company, offers customized carbon fiber processing products to meet the unique needs of its customers. With a wide range of capabilities, Krosino can manufacture carbon fiber tubes, carbon fiber profiles, carbon fiber sheets, and carbon fiber plate cut-outs, among other products, according to customer specifications. Whether it's a complex carbon fiber shape or a simple carbon fiber component, Krosino's experienced team of engineers and technicians work closely with customers to design, prototype, and produce high-quality carbon fiber products that meet their specific requirements.

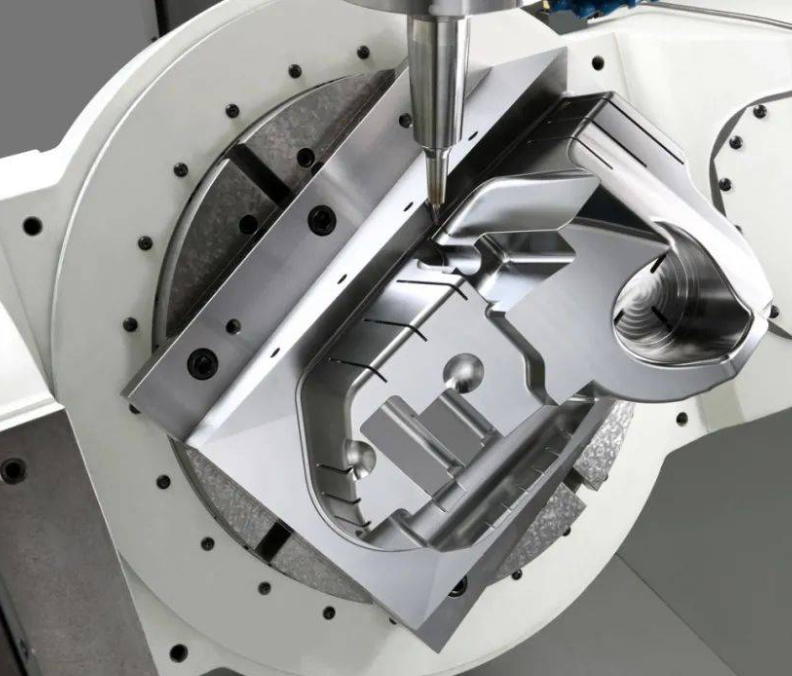

One of the key strengths of Krosino is its state-of-the-art manufacturing facilities, which are equipped with advanced equipment for carbon fiber processing. This includes precision cutting machines, CNC machining centers, autoclaves for curing, and other specialized tools for carbon fiber fabrication.

In addition to its advanced manufacturing capabilities, Krosino also places a strong emphasis on material quality and performance. The company sources high-quality carbon fiber raw materials from trusted suppliers and conducts rigorous testing and quality control processes throughout the production process to ensure that the finished products meet the highest standards. This commitment to quality ensures that Krosino's carbon fiber products exhibit excellent mechanical properties, including high strength-to-weight ratio, low weight, and excellent corrosion resistance, making them ideal for a wide range of applications.

Moreover, Krosino's expertise in customization allows customers to tailor their carbon fiber products to their specific requirements. Whether it's a unique shape, size, or surface finish, Krosino can accommodate various customization requests, providing customers with a truly bespoke solution. The company's experienced team of engineers and technicians work closely with customers, providing technical expertise and guidance throughout the design and manufacturing process, ensuring that the final products meet the desired specifications.

Furthermore, Krosino is committed to providing exceptional customer service, with a focus on responsiveness, reliability, and flexibility. The company maintains open communication channels with customers, providing regular updates on the progress of their orders and promptly addressing any questions or concerns. With efficient production processes and streamlined logistics, Krosino strives to deliver carbon fiber products on time and in accordance with customer requirements.

CNC Machining, Laser Cutting, and Bending Services by Krosino

CNC Machining, Laser Cutting, and Bending Services by Krosino

Revolutionizing Manufacturing: Advantages of CNC Machining in Manufacturing

Revolutionizing Manufacturing: Advantages of CNC Machining in Manufacturing

Unleashing Precision: Exploring CNC 5-Axis Machining

Unleashing Precision: Exploring CNC 5-Axis Machining

Krosino Company's CNC Machining Service for Global Customers

Krosino Company's CNC Machining Service for Global Customers