SHEET METAL

Sheet Metal Processing Capabilities

KROSINO IS EXPERT IN CNC MILLING | CNC TURNING|LASER CUTTING|SHEET METAL|WIRE EDM.

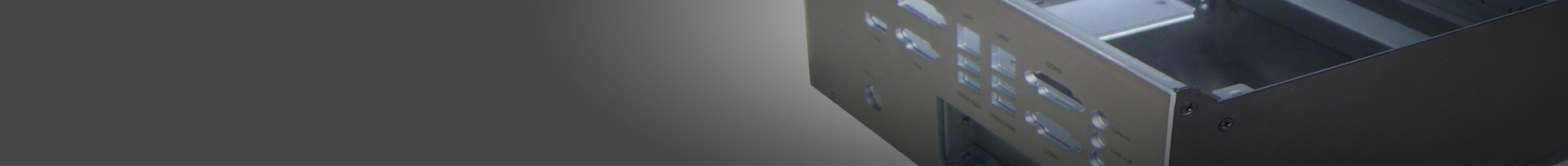

KROSINO offers custom SHEET METAL services for different metal parts.With using mark, cut, bent,drill or punch a material to form custom shapes. Its unique design and operation make it highly accurate, especially when cutting intricate shapes and small holes. Whatever products you need, our experienced teams can provide them with high standards and cost-effectiveness. We also have many surface finish options so that your machined parts are exactly what you need it to be..

Advantages&Application

of SHEET METAL Processing

SHEET METAL

KROSINO offers custom SHEET METAL services for different metal parts.With using mark, cut, bent,drill or punch a material to form custom shapes. Its unique design and operation make it highly accurate, especially when cutting intricate shapes and small holes. Whatever products you need, our experienced teams can provide them with high standards and cost-effectiveness. We also have many surface finish options so that your machined parts are exactly what you need it to be..

Advantages&Application

of SHEET METAL Processing

ADVANTAGE:

>Easy to Transport: In general, thin sheet metal is low in weight and gauge. This makes it very easy to transport and easy to work with and install, as well.

>Economical: Sheet metal is light, high-quality, and efficient. It is also very affordable, which means customers can purchase it because of its low cost

>Variety: There are several different types of sheet metal, such as thin aluminum strips, thin sheet metal, and stainless steel. It is even possible to find copper sheet metal for sale, as well as brass and copper sheets. With all these varieties of sheet metals, it means that the materials are available in abundance.

>Accuracy: Sheet metal projects can be completed using modern technology. The sheet metal works very well with a punch press, for example. And measurements are extremely accurate, also, because of the use of computerized technology.

>Durability: Sheet metal can be formed into many shapes. It creates a very durable surface. This makes it ideal for use in many different climates and many different weather conditions, including extreme hot and cold temperatures.

APPLICATION:

Sheet metal parts are found almost everywhere. Sheet metals are used in many intense industries, including aerospace, automotive, electronics, and farming. Their high strength and versatility make them ideal materials for parts like enclosures, brackets, assemblies, weldments, cabinets, and housings, as well as prototypes. .

>Easy to Transport: In general, thin sheet metal is low in weight and gauge. This makes it very easy to transport and easy to work with and install, as well.

>Economical: Sheet metal is light, high-quality, and efficient. It is also very affordable, which means customers can purchase it because of its low cost

>Variety: There are several different types of sheet metal, such as thin aluminum strips, thin sheet metal, and stainless steel. It is even possible to find copper sheet metal for sale, as well as brass and copper sheets. With all these varieties of sheet metals, it means that the materials are available in abundance.

>Accuracy: Sheet metal projects can be completed using modern technology. The sheet metal works very well with a punch press, for example. And measurements are extremely accurate, also, because of the use of computerized technology.

>Durability: Sheet metal can be formed into many shapes. It creates a very durable surface. This makes it ideal for use in many different climates and many different weather conditions, including extreme hot and cold temperatures.

APPLICATION:

Sheet metal parts are found almost everywhere. Sheet metals are used in many intense industries, including aerospace, automotive, electronics, and farming. Their high strength and versatility make them ideal materials for parts like enclosures, brackets, assemblies, weldments, cabinets, and housings, as well as prototypes. .

What Is Sheet metal processing?

Material Comparison Guide

Material Comparison GuideChoose from hundreds of manufacturing materials including various grades of thermoplastics, metals, and elastomers.

When selecting a material, consider the material properties, manufacturability characteristics, cosmetic appearance, and cost.

The sheet metal materials commonly used for the processing of sheet metal includes cold rolled sheet(SPCC), hot-rolled plate (SHCC), galvanized sheet (SECC, SGCC), aluminum plate (6061,5052,1010,1060,6063, hard aluminum, etc.) and stainless steel (mirror surface, a wire-drawing surface, a fog surface). It is generally necessary to consider the use and cost of the product.

Why Choose Krosino's Sheet Metal Service ?

——————————

Krosino offers one-stop Parts solutions .no matter what you need ,a single part,a small batch of prototypes or mass production

FROM PROTOTYPING TO LOW-VOLUME PRODUCTION

————————————

- Faster Delivery time

KROSINO could make the customized spare parts to be produced within a few hours. Once you contact us, we will send you a quote within 2 hours and kick off the project within your timeline.

- Customized Surface Finish

KROSINO provides high quality surface finishing service for your project. High-quality parts with the smooth finishes of your choice.

- One-stop supply all the machining parts that you need

KROSINO gives you one-stop parts manufacture and associated products procurement,simplify your workload ,save your time and reduce the purchase cost.

________________________________________________________________________________________________________

- Comprehensive Machining Capabilities

KROSINO has cooperated with many industrial manufacturers , procurement of raw material,production of sample,mass production of cargo, package of goods, Purchase of associated products ,surface finish of your parts and many other works all could be done by us.

- Experienced Team

KROSINO's engineers have been accumulated years of experience in creating custom parts,we could solve your question at any time.

Krosino also has a well-equipped quality assurance department and a quality management system. Our professionally trained QC will monitor all the machining processes to ensure that your projects meet strict quality specifications.

- High Quality Material Suppliers

Krosino has cooperated with many excellent material suppliers to make the raw material come with high quality ,in order to reduce the defect rate from the beginning.

The Ordering Process for Sheet metal Quotes

In Just 3 Steps

WHAT DO YOU NEED TO KNOW ABOUT ?

______________________

WHAT DO YOU NEED TO KNOW ABOUT ?

______________________

sheet Metal processing FAQs

Q1.How do I get a manufacturing quote?

Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.) ,quantity, application or samples.

Krosino gives you instant pricing and lead times for your custom parts.You could send the drawings online or to our mailbox :charles911(at)sinomechatronic.com.

In most cases, we respond Quotation within 24 business hours of receiving an RFQ. If the quote is delayed, we will notify you as soon as possible.

Q2.Who is responsible for my project?

Each project is assigned a sales staff and our project engineer, who will be there from project launch to the delivery of your parts.

Q3.What file types do you support for an instant quote?

Krosino prefers 3D CAD file in format STEP, IGS, STL.

2D CAD drawings with reference dimensions in format DWG and PDF.

2D CAD drawings with reference dimensions in format DWG and PDF.

Q4.What is your MOQ(minimum order quantity)?

No minimum order quantity requirements.MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Our services can support your scale from one-off prototypes all the way to mid- and high-volume production.

Q5.What is the production period?

It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers' requirement

by adjusting our workshop schedule.

by adjusting our workshop schedule.

Q6. Is it possible to know how is my product going on without visiting your company?

In accordance with your request, we will offer a detailed products schedule and send weekly reports with digital pictures and

videos which show the machining progress.

Q7.What are the shipping terms?

Our standard terms are ExW/FOB/CFR for rapid prototyping and regular production orders. We also offer terms of Delivery At Place(DAP) by Fedex/UPS/DHL Express, customers are responsible for import duties and fees associated with international shipping. Customers also have the option to use their own shipping accounts (e.g. DHL,FedEx or UPS) during checkout if applicable.

Q8.What tolerances can Krosino's CNC machining achieve?

There is not a given set of tolerances that fits all processes and materials. In every case, the final tolerances on your part will depend on a number of factors, including but not limited to: part size, design geometry,

materials, surface finish.

materials, surface finish.

Krosino's general tolerance is applied to ISO 2768 (medium) for machined plastic and ISO 2768 (fine) for machined metals.

Q9.How does Krosino ensure the quality of my parts?

Krosino takes a proactive approach to customer's quality concerns from the initial communication, providing cost-effective and rationalized advice from designs, materials, production processes, manufacturability, etc.

Once your order is confirmed, we will perform a full Design for Manufacturing (DFM) review to point out any issues that may affect the quality of your parts.

We have the ability to share inspection data with you in real-time so we can work together to address any quality issues you may have during production. All incoming materials will meet your design specifications.

Even if you received defective parts ,you could show us directly , we will check and negotiate a quick solution to solve the problem . Including but not limited to :free remaking the defective parts(if only a little defective parts),free remaking full order or refund the money directly (if defective parts more than 60%)

Message

If you have any suggestions or question for us.Please contact us.