Revolutionizing Manufacturing: The Advantages of CNC Machining

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. Among the technologies driving this evolution, Computer Numerical Control (CNC) machining stands out as a game-changer. This innovative method of manufacturing has revolutionized production processes across industries. Let's delve into the myriad advantages that CNC machining offers.

One of the most significant advantages of CNC machining is its unparalleled precision. Traditional manufacturing methods often rely heavily on manual intervention, leading to human errors. However, CNC machines operate with extraordinary accuracy, executing tasks with microscopic precision. This precision ensures consistent quality in every component manufactured, meeting the most stringent specifications.

CNC machining optimizes production workflows, significantly enhancing efficiency. Unlike manual machining, where operators are limited by their physical endurance and skill level, CNC machines operate tirelessly and consistently. They can run continuously, reducing downtime and maximizing productivity. Moreover, CNC machines can perform complex operations with ease, minimizing the need for multiple setups and tool changes, further streamlining the manufacturing process.

CNC machining offers unparalleled versatility, capable of producing a diverse range of components across various industries. Whether it's aerospace, automotive, electronics, or healthcare, CNC machines can adapt to different materials, including metals, plastics, and composites. Additionally, they can execute a multitude of operations such as milling, drilling, turning, and grinding, providing manufacturers with the flexibility to tackle diverse manufacturing challenges.

Scalability is a critical factor in modern manufacturing, especially with fluctuating demand and evolving market trends. CNC machining facilitates seamless scalability, allowing manufacturers to ramp up or scale down production as needed. With minimal setup time and the ability to replicate designs accurately, CNC machines empower businesses to respond swiftly to market demands, thereby enhancing their competitiveness.

While the initial investment in CNC machining may seem substantial, its long-term cost-effectiveness is undeniable. The automation and precision offered by CNC machines reduce material wastage and minimize the need for rework, leading to significant cost savings in the long run. Moreover, the efficiency gains and shorter lead times associated with CNC machining translate into improved profitability for manufacturers.

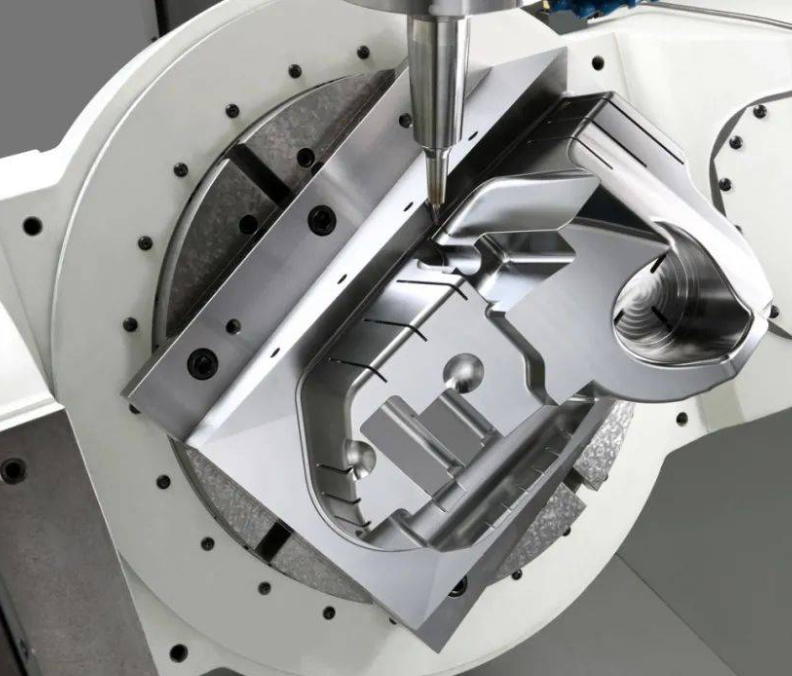

Innovation is the lifeblood of manufacturing, driving advancements in product design and functionality. CNC machining facilitates innovation by enabling the production of intricate and complex geometries that would be challenging or impossible to achieve using traditional methods. This opens up new possibilities in product development, allowing engineers to push the boundaries of design without compromising on manufacturability.

In today's highly competitive market, maintaining high-quality standards is non-negotiable. CNC machining ensures superior quality and consistency by eliminating the variability inherent in manual processes. Every component produced undergoes rigorous inspection, adhering to strict quality control measures. This not only enhances product reliability but also instills confidence in customers, fostering long-term relationships and brand loyalty.

In conclusion, CNC machining has emerged as a cornerstone of modern manufacturing, offering a plethora of advantages that drive efficiency, precision, and innovation. Its versatility, scalability, and cost-effectiveness make it indispensable across industries, from aerospace and automotive to healthcare and consumer electronics. As technology continues to evolve, CNC machining will undoubtedly play a pivotal role in shaping the future of manufacturing, empowering businesses to thrive in an increasingly competitive global market.

CNC Machining, Laser Cutting, and Bending Services by Krosino

CNC Machining, Laser Cutting, and Bending Services by Krosino

Unleashing Precision: Exploring CNC 5-Axis Machining

Unleashing Precision: Exploring CNC 5-Axis Machining

Krosino Company's CNC Machining Service for Global Customers

Krosino Company's CNC Machining Service for Global Customers

Krosino Company helps overseas customer complete production and assembly of small packaging machine with exceptional service

Krosino Company helps overseas customer complete production and assembly of small packaging machine with exceptional service