Introduction:

In recent years, 3D printing has emerged as a groundbreaking technology that has revolutionized the manufacturing industry. Also known as additive manufacturing, 3D printing enables the creation of three-dimensional objects from digital models by layering materials on top of each other. This innovative process offers numerous advantages, including increased design freedom, reduced costs, and enhanced customization, making it a game-changer for industries ranging from aerospace to healthcare.

Characteristics of 3D Printing:

At the heart of 3D printing is the layer-by-layer additive manufacturing process, which differentiates it from traditional subtractive manufacturing methods. In 3D printing, the object is built layer by layer, with the material being added in a controlled manner according to the design specifications. This allows for highly complex and intricate geometries to be created with precision, without the need for expensive tooling or molds. 3D printing can work with a wide range of materials, including plastics, metals, ceramics, and composites, providing versatility in terms of material properties and applications.

Advantages of 3D Printing:

3D printing offers several advantages over traditional manufacturing methods:

Design Freedom: One of the significant advantages of 3D printing is the unparalleled design freedom it offers. Complex shapes, internal structures, and intricate details that are impossible or costly to manufacture with traditional methods can be easily produced using 3D printing. This allows for creative and innovative designs that were previously unattainable.

Cost-effective: 3D printing eliminates the need for costly tooling, molds, and fixtures, which are required in traditional manufacturing. This significantly reduces upfront costs, making it cost-effective for small production runs or custom manufacturing. Additionally, 3D printing enables on-demand manufacturing, reducing inventory costs and wastage of materials.

Customization: 3D printing allows for high levels of customization, as each object can be easily modified or personalized without additional tooling or setup. This makes it ideal for producing one-of-a-kind or personalized products, such as custom prosthetics, dental implants, or fashion accessories.

Rapid Prototyping: 3D printing enables rapid prototyping, allowing for quick iteration and design optimization. This significantly reduces the time and cost involved in the product development cycle, enabling faster time-to-market for new products.

Sustainability: 3D printing can be more environmentally friendly compared to traditional manufacturing methods, as it generates less waste, consumes less energy, and has the potential for using recycled materials. It also enables local production, reducing the carbon footprint associated with transportation and logistics.

Disadvantages of 3D Printing:

While 3D printing has numerous advantages, there are some limitations and challenges associated with the technology:

Limited Material Properties: Although 3D printing can work with a wide range of materials, the material properties may not be on par with those achieved through traditional manufacturing methods. For example, the strength, durability, and heat resistance of 3D printed parts may not be suitable for some demanding applications.

Printing Speed: 3D printing can be relatively slow compared to traditional manufacturing methods, especially for large or complex objects. The printing time can vary depending on the complexity, size, and material used, which may impact the overall production timeline.

Post-Processing Requirements: 3D printed objects often require post-processing, such as sanding, polishing, or painting, to achieve the desired finish or surface quality. This additional step may add to the production time and cost.

Limited Scalability: While 3D printing is ideal for small production runs or custom manufacturing, it may not be as efficient for mass production. The printing time and cost may not be viable for large quantities of identical parts, making traditional manufacturing methods more economical in such cases.

Material Availability: While 3D printing has a wide range of materials to choose from, not all materials are readily available for 3D printing. Some advanced or specialized materials may be expensive or challenging to obtain, limiting the options for certain applications.

Processing Precautions:

To ensure successful 3D printing, some precautions need to be taken during the process:

Material Selection: Choosing the right material for the intended application is crucial. Material properties such as strength, flexibility, and heat resistance should be considered to ensure that the printed object performs as intended.

Print Settings: Accurate control of print settings, such as temperature, speed, and layer height, is critical for achieving desired print quality. Incorrect settings can result in poor print quality, weak parts, or even print failures.

Design Considerations: Designing for 3D printing requires careful consideration of factors such as overhangs, support structures, and tolerances. Designing with these factors in mind can help prevent issues like print failures or poor surface quality.

Post-Processing: Post-processing steps, such as removing support structures, sanding, or painting, may be required to achieve the desired finish or functionality. Proper post-processing techniques should be followed to avoid damaging the printed object.

Main Uses of 3D Printing:

3D printing has found applications across a wide range of industries, including:

Prototyping: 3D printing is widely used for rapid prototyping, allowing for quick and cost-effective iteration of product designs before mass production.

Aerospace: 3D printing is used in aerospace for manufacturing lightweight, complex, and high-performance parts, such as engine components and structural elements, to reduce weight and improve efficiency.

Healthcare: 3D printing has revolutionized the field of healthcare by enabling the production of custom prosthetics, implants, surgical guides, and models for surgical planning, leading to improved patient care and outcomes.

Automotive: 3D printing is used in the automotive industry for producing prototypes, tooling, and customized parts, as well as for manufacturing lightweight components to improve fuel efficiency.

Architecture and Construction: 3D printing is used in architecture and construction for creating intricate models, prototypes, and building components, enabling faster and more efficient construction processes.

Consumer Goods: 3D printing is used in the production of consumer goods such as jewelry, fashion accessories, and home decor, allowing for customization and unique designs.

Cost of 3D Printing:

The cost of 3D printing can vary depending on various factors, including the type of printer, material used, object size, complexity, and desired finish. 3D printers can range from affordable desktop printers for home or small-scale use to large industrial printers for mass production, which can be significantly more expensive. The cost of materials also varies, with some specialized or high-performance materials being more expensive than standard materials. Additionally, post-processing, labor, and overhead costs should be taken into account when calculating the overall cost of 3D printing.

Conclusion:

3D printing is a groundbreaking technology that is transforming the manufacturing industry by offering unprecedented design freedom, cost-effective production, customization, and rapid prototyping. Despite some limitations, 3D printing has found numerous applications across various industries, and its potential continues to expand as the technology advances. With careful consideration of material selection, print settings, design, and post-processing, 3D printing offers significant advantages and opportunities for innovation in the manufacturing world.

CNC Machining, Laser Cutting, and Bending Services by Krosino

CNC Machining, Laser Cutting, and Bending Services by Krosino

Revolutionizing Manufacturing: Advantages of CNC Machining in Manufacturing

Revolutionizing Manufacturing: Advantages of CNC Machining in Manufacturing

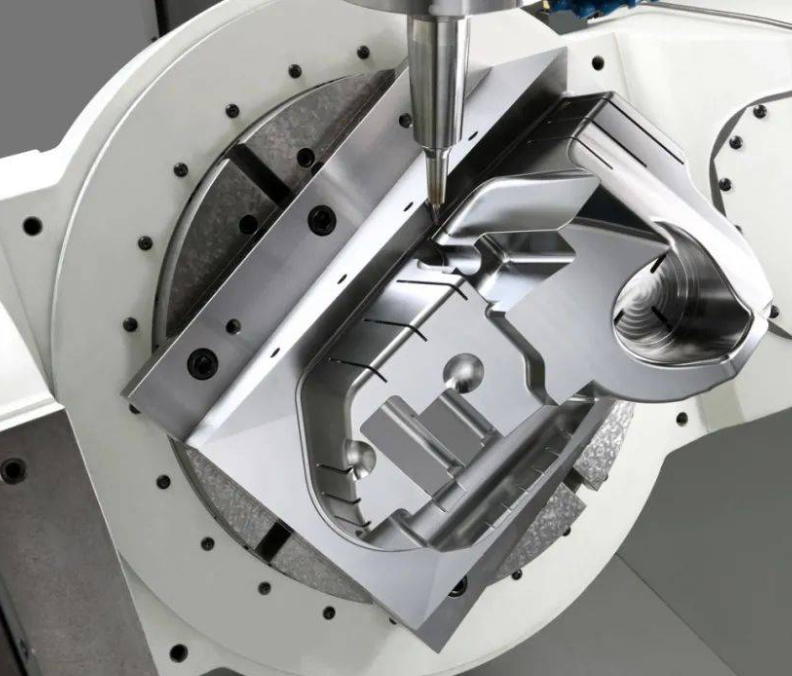

Unleashing Precision: Exploring CNC 5-Axis Machining

Unleashing Precision: Exploring CNC 5-Axis Machining

Krosino Company's CNC Machining Service for Global Customers

Krosino Company's CNC Machining Service for Global Customers