What's the Difference Between 3-axis, 4-axis & 5-axis Machining?

CNC machining has grown into one of the most critical manufacturing processes used in workshops around the world. Adding computer control to a previously manual process enables a leap in the accuracy and precision of machined parts.

In addition, due to the increasingly complex requirements of various industries, CNC machine tools have undergone several evolutions to better meet the needs of customers.

The development of CNC machining technology has spawned various forms and variations of this technology. These include 3-axis, 4-axis and 5-axis CNC machines.

At Krosino, we have a range of state of the art 3-axis, 4-axis and 5-axis milling machines. As a designer, having an understanding of which type of machine your part will be manufactured on is critical in optimising your design. When designing a CNC machined part, you might not have thought about which type of machine your part will be machined on, but the complexity and type of geometry you can design will be different for different types of machines.

The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be.

As a leading provider of CNC machining services, we often receive questions from our customers about how these technologies work. So, we decided to learn more about them through this article.

This post will focus on how each technology works, advantages, disadvantages, and applications. Most importantly, we'll show you how to choose the best type of CNC machining for your project.

WHAT IS 3-AXIS MACHINING ?

3-AXIS MACHINING

The most simple type of machining, where the workpiece is fixed in a single position. Movement of the spindle is available in the X, Y and Z linear directions.

The cutting tool moves along the X, Y, and Z axes to trim excess material from the part. Additionally, it can even move along these multiple axes simultaneously to create the desired design.

This means that CNC machines can cut into the workpiece from side to side, front to back, up and down. However, the table holding the workpiece cannot move freely at all.

3-axis machines are typically used for machining of 2D and 2.5D geometry. Machining of all 6 sides of a part is possible in 3 axis machining but a new fixturing set-up is required for each side, which could be expensive (more on that below). For a single fixture setup, only one side of the part can be machined.

Advantage

Although more advanced systems are available in the industry today, 3-axis CNC machining is still widely used. So, let's take a look at some of the advantages of keeping it.

-Low cost

3-axis CNC machining is best for quick production of basic geometries and simple parts. Also, in 3-axis machining, it is relatively easy to program and set up the computer for a production run.

-Versatility

3 axis CNC machining is a highly versatile part manufacturing process. Drilling, milling and even turning can be performed by simply changing the tool.

Many complex and practical shapes can be manufactured by 3 axis CNC milling, especially when in the hands of a world class CNC machining facility. 3-axis machining is best suited to manufacture of planar milled profiles, drillings & threaded holes in-line with an axis. Undercut features are possible with the use of T-slot cutters and Dovetail milling cutters.

These machines also integrate automatic tool changers, extending their capabilities.

Shortcoming

However, sometimes the designed feature physically cannot be manufactured by a 3-axis machine, or the feature might be more economically viable to machine with a 4 or 5 axis machine.

Features not possible in 3 axis milling include any features on an angle to the X-Y-Z co-ordinate system, even if the feature itself is planar. There are two types of angled features you can design, and understanding the distinction between them is important when designing parts for CNC milling.

3-axis machining is also hindered by a number of factors that make it impossible to meet all machining needs. Some of these factors include:

-Design limited

With 3-axis CNC machining, you are limited to basic shapes and geometries, for example, it cannot create undercut features. While the machine can do more in the hands of a skilled machinist, it still can't match the complex shapes achievable with 4- and 5-axis CNC machines.

Additionally, it is not suitable for machining parts with exceptionally deep features or narrow cavities.

-Various settings

Since the table holding the workpiece is stationary, the machinist has to change its orientation several times to machine its other faces.

This repositioning results in a loss of accuracy, not to mention the time wasted doing so.

-Poor surface finish

The surface finish obtained with 3-axis machining is relatively poor, especially on Z cuts. This happens because the tool is long. As a result, it experiences more vibration, which can ruin the finish of the product.

3-axis CNC machining is still a very useful process. We can use it to create a variety of high-precision basic geometries

These applications include:

2 and 2.5D pattern engraving

Slot and face milling

The threaded holes are aligned with the machine axis.

Drilling etc.

WHAT IS 4-AXIS MACHINING ?

4-AXIS MACHINING

This adds a rotation about the X-axis, called the A-axis. The spindle has 3 linear axes of movement (X-Y-Z), like in 3-axis machining, plus the A-axis occurs by rotation of the workpiece. There are a few different arrangements for 4 axis machines, but typically they are of the ‘vertical machining’ type, where the spindle rotates about the Z axis. The workpiece is mounted in the X-axis and can rotate with the fixture in the A-axis. For a single fixture setup, 4 sides of the part can be machined.

4-axis CNC machining offers a significant upgrade over 3-axis machining. It adds additional degrees of freedom through rotational motion, making machining complex features possible and more straightforward.

In 4-axis CNC machining, the tool moves freely in the X, Y, and Z axes to machine the workpiece. However, the workpiece does not stand still on the table like in 3-axis machining.

A 4-axis CNC machine can rotate a workpiece around the X-axis in a plane called the A-axis. So as the tool moves along the workpiece and the table turns it, you can cut along the contour of the workpiece.

Advantage

Many advantages come from choosing a 4-axis CNC machine for your manufacturing project. Here are some of them Enables higher design complexity

Since the table rotates around the X axis, the 4-axis CNC machine can produce intricately detailed parts. Additionally, the extra rotation enables it to access and machine parts on other faces at odd angles to create the final part.

-High precision and accuracy

The 4-axis CNC machine can access multiple faces of the workpiece without adjusting or changing fixtures. As a result, parts made with it are very accurate and meet exacting standards.

-Higher speed and lower production costs

Most work done on a 4-axis CNC machine requires only one set-up. As a result, work can proceed smoothly without downtime or intervention to change fixtures and tools.

In addition, since multiple fixtures are not required to hold the part, production costs are significantly reduced, especially compared to 3-axis machining.

Shortcoming

4-axis CNC machines also have some flaws that may make them unsuitable for some customers. Let's take a look at them

-High running cost

The cost of running a 4-axis CNC machine is relatively high compared to running a 3-axis CNC machine. This is due to the extra features of the machine and the extra labor required to operate the machine.

4-axis CNC machining opens up a wide range of manufacturing possibilities. Some of its applications include:

Curved geometry

Engraving or machining cylinder sides and contours

Turning and milling (on the same machine).

Cut side holes and pockets.

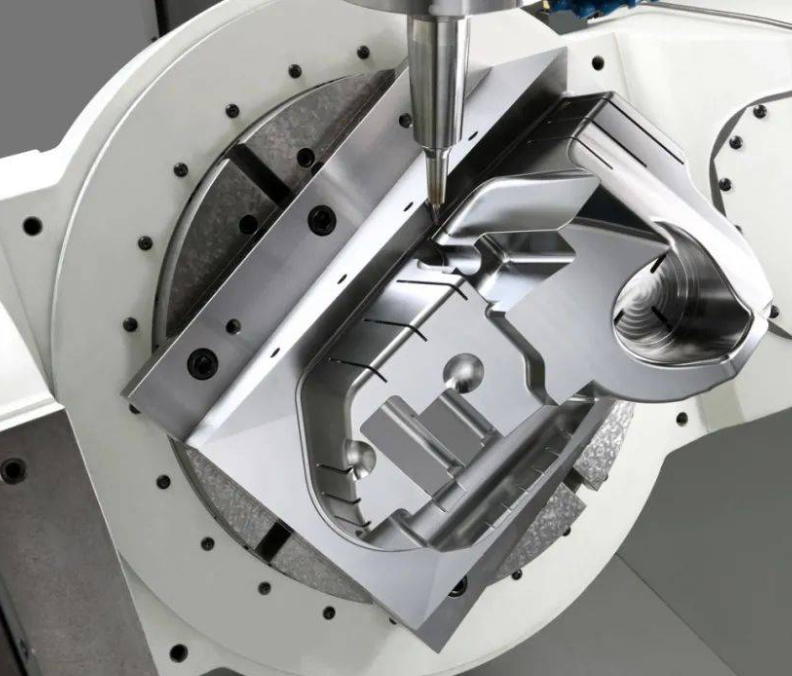

WHAT IS 5-AXIS MACHINING ?

5-AXIS MACHINING

These CNC milling machines utilise 2 of the 3 possible rotation axis, depending on the type of machine. A machine will either utilise a rotation in the A-axis and C-axis, or a rotation in the B-axis and C-axis. The rotation either occurs by the workpiece, or by the spindle.

There are two main types of 5-axis CNC machines, 3+2 machines, and fully continuous 5-axis machines.

In 3+2 axis machining two rotational axes operate independently to each other, meaning that the workpiece can be rotated to any compound angle in relation to the cutting tool for features to be machined. However, two axes rotation at the same time as machining is not possible. 3+2 machining can produce highly complex 3D shapes. Fully continuous 5-axis machining can simultaneously rotate the two rotation axis, at the same time as machining and the cutting tool moving linearly in XYZ co-ordinates.

5-axis machining is the most accurate and advanced method of manufacturing complex, precision metal parts on the shop floor.

In a 5-axis CNC machine, the tool moves in the X, Y, and Z axes, just like in a 3-axis machine. In addition to this, the table can also rotate the workpiece around the X and Y axes.

These planes of rotation are called the A and B axes, respectively.

These extra rotations open up other faces of the workpiece that were previously impossible to machine. Therefore, for a 5-axis machine, accurate 3D machining is possible since the machine moves in the XYZ axes and rotates in the A and B planes simultaneously.

Advantage

There are many advantages to using a quality 5-axis CNC machining service.

-Complex Part Creation

Because of this, 5-axis CNC machining is very popular in the aerospace, automotive and energy industries.

It can handle a wide variety of curved geometries, narrow cavities, overhanging features, and more that other machining methods can’t even cover.

-Shorten delivery time

Making parts with a 5-axis CNC machine is a very fast job. It does not require multiple setups to change fixture or part orientation. It can create incredibly complex shapes in one single-step machining process.

-Incredible surface finish

5 axis machine can orient the part closer to the cutting tool. This results in a cleaner, more accurate cut for a top-notch surface finish.

Shortcoming

The only downside to 5-axis CNC machining is its cost. The great service and features it offers make it more expensive than 3-axis and 4-axis machining.

However, for applications that require ultra-high quality, the extra cost is worth it.

Some typical applications for 5-axis machining include:

Machining complex shapes

Create sloped surfaces

High Precision, Low Tolerance Applications

Understanding the difference between 4-axis CNC machining and 5-axis CNC machining is a step toward the right product. This is because most CNC machines use 3-, 4-, and 5-axis CNC machining processes.

CNC Machining, Laser Cutting, and Bending Services by Krosino

CNC Machining, Laser Cutting, and Bending Services by Krosino

Revolutionizing Manufacturing: Advantages of CNC Machining in Manufacturing

Revolutionizing Manufacturing: Advantages of CNC Machining in Manufacturing

Unleashing Precision: Exploring CNC 5-Axis Machining

Unleashing Precision: Exploring CNC 5-Axis Machining

Krosino Company's CNC Machining Service for Global Customers

Krosino Company's CNC Machining Service for Global Customers