CNC machine is digital controlled machine , can be divided into metal cutting machine, metal forming machine, special processing machine , measuring and drawing machine, product categories and specifications, a wide range of industry application scenarios Machine is called "working mother machine", its technical level and product quality is an important sign to measure the development level of equipment manufacturing industry. Our country is a major production country of CNC machine tools, and the industrial scale accounts for more than 78%. In recent years, the scale of our numerical control machine tool industry continues to expand. In 2021, the number of Chinese CNC machine tool industry will reach 358.90 billion yuan, with a year-on-year growth of 10.4%. It is expected that the numerical control machine tool industry scale of our country will amount to 4090.0 billion yuan in 2023.

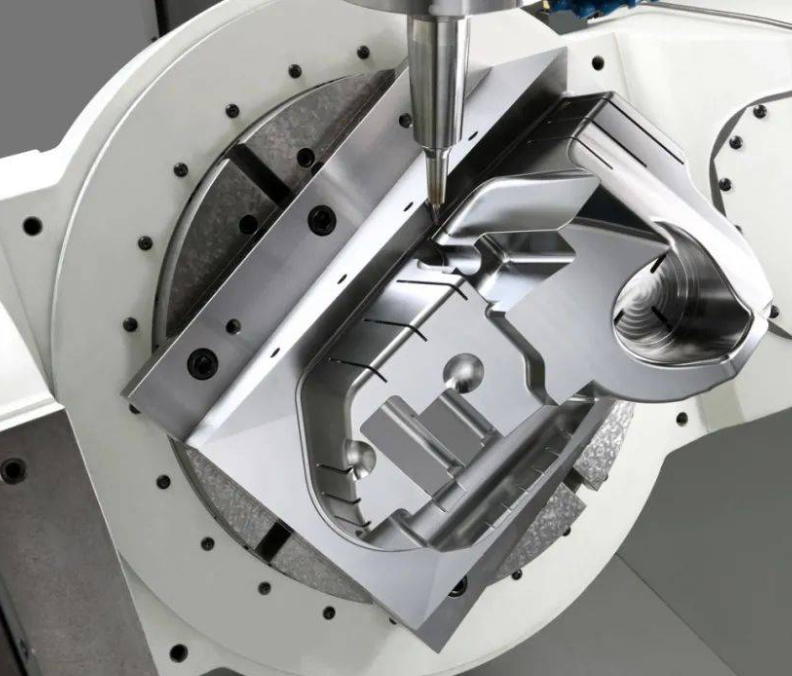

China's CNC machine tools have made certain achievements: high - grade CNC machine tools develop rapidly. China's CNC machine tools have made great progress in a series of important technologies such as composite processing, digital design and five-axis linkage. The development of independent five-axis CNC machine tools, ultra-precision CNC machine tools and many high-performance machine tools, the development of some intermediate CNC machine tools industrialization base.

From the industrial structure, Chinese CNC metal cutting machine tool industry scale is the largest, accounting for 53.2%, CNC metal forming machine tool follows, the industrial scale accounts for 28.5%, CNC special processing machine tool industry scale accounts for quite small only 17.0%(Data source: China Business Industry Research Institute) Manufacturing quality and technical level has been continuously improved. CNC machine tools in manufacturing quality and improve the technical level, enhance the function of CNC machine tools more and more perfect, some performance indicators almost reached the international advanced level. A range of high-performance functional prototypes can be developed, including CNC turntables, linear televisions, A/C axis CNC milling heads, high speed, high speed spindle units, digital instrumentation tool systems, etc. Some component prototypes have been produced on a small scale.

Statistics show that as of November 29, 2022, the number of enterprises in China's CNC machine tool industry established in 2022 was 22,488. From the data of 2010-2021, the number of CNC machine tool industry enterprises established in 2021 was the largest, reaching 24,762, an increase of 46.5% compared with the previous year; The fastest growth rate will be 110.7% in 2020. From the perspective of provinces and cities, by November 29, 2022, the number of CNC machine tool industry enterprises in China is the largest in Jiangsu Province, a total of 24,405; The top 10 regions by number of enterprises in the CNC machine tool industry are Jiangsu, Shandong, Guangdong, Zhejiang, Shanghai, Anhui, Liaoning, Hebei, Shaanxi and Hubei.

The number of patents related to CNC machine tools in 2021 is 5619, down 21.8% year on year. The development of high - grade numerical control system has achieved satisfactory results. Through effective technical cooperation independently researched and developed by China, the medium-range CNC system has become more advanced in production and development technology. The problems of remote data transmission and multi - coordinate linkage are solved. In order to meet the requirements of numerical control system, a spindle AC control system and an AC drive system were established, bringing a series of products. But China's CNC machine tools are still faced with many constraints, compared with foreign products, China's CNC machine tools gap is mainly in the high speed, high efficiency and precision of machine tools.

According to the "2022-2027 China CNC machine tool industry market Panorama survey and Development Prospect Forecast Report" released by the Puhua Industrial Research Institute:

China has become a leading manufacturing country in the world in terms of the range of manufacturing products and the amount of money. According to the National Bureau of Statistics, the scale of China's manufacturing industry continued to grow from 2004 to 2019. In 2019, China's manufacturing GDP reached 26.92 trillion yuan. The rapid development of the manufacturing industry has increased the demand for CNC machine tools and other production machines.

In 2020, the top three companies in the market share of China's CNC machine tool industry are Genesis, Qinchuan Machine Tool and Haitian Seiko, with the market share of 23.81%, 13.47% and 12.62%, increasing by 5.94, 1.75 and 3.42 percentage points respectively; The market share of Huadong Heavy Machinery, which ranked third in 2019, was only 3.27% in 2020.

Market competition pattern analysis of machine tool industry

With the optimization and upgrading of China's industrial structure, China is experiencing an important stage from high-speed development to high-quality development. As an industrial mother machine, the processing precision, efficiency, stability and other fine indicators are gradually improved, and the demand for middle and high-end products is increasing. In this context, the structure of the machine tool market in China will be upgraded to complete sets of automation, customer customization and general shift upgrading direction, products from ordinary machine tools to CNC machine tools, from low-grade CNC machine tools to mid-grade CNC machine tools upgrade.

China's machine tool industry is currently large but not strong, and it is urgent to have a "Huawei" in the machine tool industry to promote and guide the further development of the machine tool industry to the high-end. The major machine tool manufacturers in the world include Germany, Japan, the United States, China and so on. China's machine tool industry started late, but the overall development is rapid. Government industrial policies have played a certain guiding role in the innovation and development of the machine tool industry. China's machine tool industry has grown significantly in terms of technology and market size, and China has become the world's largest machine tool production and marketing country. Data show that China recorded its first trade surplus in the machine tool industry in 2019. The decline in demand for imported machine tools is mainly due to import substitution in some sectors of domestic products, while trade friction between China and the United States has increased import restrictions on high-end machine tools.

Numerical control machine tool future development trend and space forecast

As the international situation continues to evolve, Western countries continue to strengthen their technological blockade against China. Some high-end five-axis CNC machine tools can not be imported from abroad, leading to the strategic equipment production of important domestic enterprises "neck" problem. The Sino-US trade friction further increases the import limitation of high-end machine tools, our aviation, space, weapons, ship, nuclear, electronic etc urgently need five-axis linkage CNC machine tools military industries face total blockade. The machine tool industry is in urgent need of upgrading the product structure and breaking through to the more high-end and high-tech machine tool market.

At present, China's manufacturing industry urgently needs to transform from "manufacturing power" to "manufacturing power". After decades of development, China's CNC machine tool industry has become the world's largest production and marketing country, the rapid development of technology and production capacity, has a response to the national manufacturing transformation of the foundation, the future demand for CNC machine tools in China will be from low to high-end transformation, in other words, high-end CNC machine tools will have a larger import replacement space.

Using a variety of unique information processing technology, Zhongresearch Priceprice collects, collates, processes, analyzes and transmits massive data in the market, provides clients with a package of information solutions and consulting services, minimizes clients' investment risks and operating costs, grasps investment opportunities and improves enterprise competitiveness.

CNC Machining, Laser Cutting, and Bending Services by Krosino

CNC Machining, Laser Cutting, and Bending Services by Krosino

Revolutionizing Manufacturing: Advantages of CNC Machining in Manufacturing

Revolutionizing Manufacturing: Advantages of CNC Machining in Manufacturing

Unleashing Precision: Exploring CNC 5-Axis Machining

Unleashing Precision: Exploring CNC 5-Axis Machining

Krosino Company's CNC Machining Service for Global Customers

Krosino Company's CNC Machining Service for Global Customers