If you're a customer looking to understand the world of CNC machines, you've come to the right place! CNC machines have revolutionized the manufacturing industry with their ability to automate and streamline various processes. We'll provide an in-depth overview of different types of CNC machines, including milling machines, lathes, routers, plasma cutters, and laser cutters. We'll explore their capabilities, applications, specifications, and common use models in China.

Milling Machines:

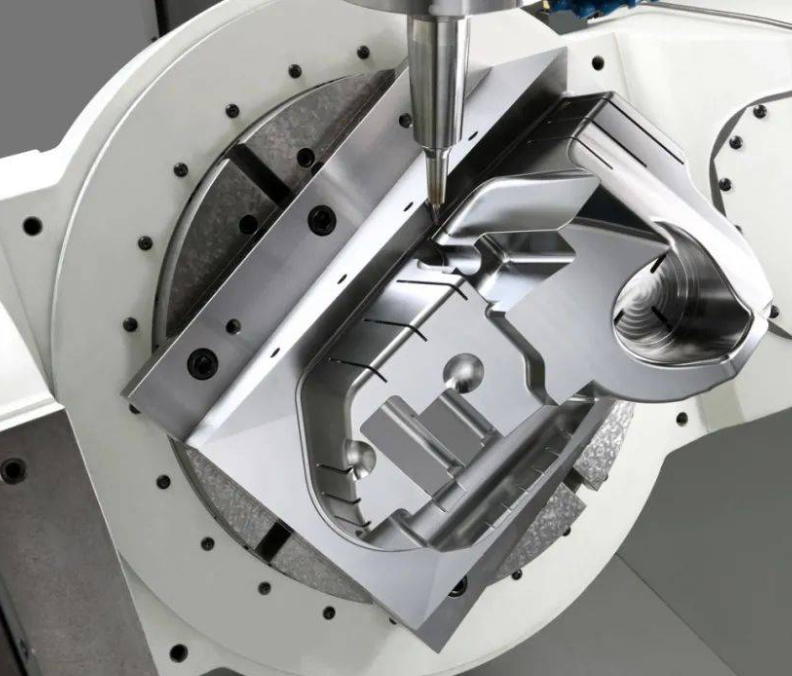

Milling machines are among the most common types of CNC machines used in manufacturing. They are used to remove material from a workpiece by rotating a cutting tool, which can be either a drill or an end mill, and moving it along multiple axes. Milling machines can perform a wide range of operations, such as cutting, drilling, shaping, and engraving. They are commonly used in industries such as automotive, aerospace, and general machining.

Some common specifications of milling machines include the number of axes (3-axis, 4-axis, or 5-axis), spindle speed, cutting capacity, and tool changer capacity. In China, popular milling machine models include the Fanuc series, Haas series, and DMG Mori series.

Lathes:

Lathes are another type of CNC machine widely used in manufacturing. They are used to rotate a workpiece and remove material from it using cutting tools. Lathes are commonly used for cylindrical or spherical machining, such as turning, facing, and threading. They are widely used in industries such as aerospace, automotive, and medical.

Some common specifications of lathes include the swing diameter (the maximum diameter of the workpiece that can be rotated), the distance between centers (the maximum length of the workpiece that can be held), spindle speed, and tool turret capacity. Popular lathe models in China include the Mazak series, Doosan series, and Okuma series.

Routers:

Routers are CNC machines used for cutting, shaping, and engraving materials such as wood, plastic, and composite materials. They are widely used in industries such as woodworking, sign-making, and furniture manufacturing. Routers use a rotating cutting tool to remove material from the workpiece, and they can move along multiple axes to create complex shapes and patterns.

Some common specifications of routers include the number of axes (3-axis, 4-axis, or 5-axis), spindle speed, cutting capacity, and the type of tooling system used (such as a collet or an automatic tool changer). Popular router models in China include the CNT series, Weeke series, and Biesse series.

Plasma Cutters:

Plasma cutters are CNC machines used for cutting through electrically conductive materials, such as steel, aluminum, and stainless steel. They use a high-velocity jet of ionized gas (plasma) to melt through the material and create a clean, precise cut. Plasma cutters are widely used in industries such as metal fabrication, automotive, and construction.

Some common specifications of plasma cutters include the cutting capacity (thickness and size of the material that can be cut), plasma generator power, and the type of control system used. Popular plasma cutter models in China include the Hypertherm series, ESAB series, and HYPERTHERM series.

Laser Cutters:

Laser cutters are CNC machines that use a high-powered laser beam to cut through a wide range of materials, such as metal, wood, acrylic, and fabric. They are known for their high precision and ability to create intricate designs. Laser cutters are widely used in industries such as aerospace, automotive, jewelry, and signage.

Some common specifications of laser cutters include laser power, cutting speed, cutting area, and the type of laser source used (such as CO2, fiber, or diode). Laser cutters can also be classified based on the number of axes (2-axis, 3-axis, or 4-axis) and the type of laser system (CO2 laser, fiber laser, or hybrid laser). Popular laser cutter models in China include the Han's Laser series, Bystronic series, and Trumpf series.

In addition to the aforementioned types of CNC machines, there are also specialized CNC machines for specific applications, such as EDM (Electrical Discharge Machining) machines for precision machining of hard materials, and wire-cut EDM machines for cutting complex shapes using a wire electrode.

In conclusion, CNC machines have transformed the manufacturing industry with their precision, speed, and automation capabilities. Milling machines, lathes, routers, plasma cutters, and laser cutters are some of the most commonly used CNC machines, each with its unique capabilities and applications. When choosing a CNC machine, it's essential to consider factors such as the type of material being processed, the desired cutting or shaping operations, and the level of precision required. Popular CNC machine models in China vary depending on the specific type and application, and it's important to research and consult with reputable manufacturers to ensure that the machine meets your requirements.

We hope this comprehensive guide provides you with valuable insights into the different types of CNC machines available in the market. If you have further questions or need specific information, feel free to consult with a reliable CNC machine manufacturer or industry expert. Happy CNC machining!

CNC Machining, Laser Cutting, and Bending Services by Krosino

CNC Machining, Laser Cutting, and Bending Services by Krosino

Revolutionizing Manufacturing: Advantages of CNC Machining in Manufacturing

Revolutionizing Manufacturing: Advantages of CNC Machining in Manufacturing

Unleashing Precision: Exploring CNC 5-Axis Machining

Unleashing Precision: Exploring CNC 5-Axis Machining

Krosino Company's CNC Machining Service for Global Customers

Krosino Company's CNC Machining Service for Global Customers