As one of the fastest-growing precision CNC machining services suppliers in China, the following machining capabilities at Krosino are available to serve your needs of CNC machining, from rapid prototyping to precision parts and tooling machining, to end-use production.

CNC Turning: a technology through which the material block fixed on the CNC turning center or lathe rotating with high speed, while the cutting tool moving into the rotating axis to process the workpiece, to get CNC turned parts with accurate sizes.

CNC Milling: generally regarded as the most common machining process, which refers to utilizing a CNC milling cutter to do circular motion and create milled parts with certain shapes and details in a stationary piece, including slots, holes, notches, grooves, etc.

CNC Drilling: a cutting process in which the workpiece is fixed, aligning the cutter center with the hole center and rotate to produce round holes, can be done on lathes and mills.

CNC Milling and Turning: a compound machining technology in which the cutting tool and workpiece are both rotating, to produce complex curved or special-shaped parts through designed multiple kinds of tasks.

Wire EDM: EDM parts from prototypes to full production with tight tolerance and complex construction.

|

1800

Factory Area

|

90~100

Employees

|

US$1500,000+

Annual Revenue

|

100+

Cooperative suppliers

|

OEM

Brands

|

| 3-AXIS MILLING | 4-AXIS MILLING | TURNING | |

| MAX. PART SIZE | • 1500 x 1100 x 500 mm • 59.0 x 43.3 x 19.6 in |

• 1500 x 1100 x 500 mm • 59.0 x 43.3 x 19.6 in |

• Ø 300 x750mm • Ø 11.8 x 29.5 in |

| MIN. FEATURE SIZE | • Ø 0.50 mm • Ø 0.019 in |

• Ø 0.50 mm • Ø 0.019 in |

•Ø 0.50 mm • Ø 0.019 in |

| TOLERANCES | ±0.01 ~ ±0.001mm ,according to customers' requests | ||

| 5-AXIS MILLING | Accept custom made from our partners | ||

When selecting a material, consider the material properties, manufacturability characteristics, cosmetic appearance, and cost.

| TYPE | MATERIAL | FINISH | |||

| ALUMINUM | AL6061,AL6063,AL6082,AL7075,AL5052 ,ETC. | Clear Anodized,Color Anodized,Sandblast ,Chemical Film,Brushing,Polishing,Chorming | |||

| STAINLESS STEEL | 201SS,301SS,303SS,SUS304,316SS ,ETC. | Heat treatment,Polishing,Passivating,Laser engraving,Brushing,Electrophoresis | |||

| STEEL | Steel,carbon steel,4140,4340,20#,45# ,ETC. | Powder Coated,Zinc Plating,Oxide Black,Nickel Plating,Chrome Plating,Heat Treatment | |||

| PLASTIC | ABS,PE,PA,POM,DELRIN,ETC. | White,Black,Blue ,Laser engraving,ETC. | |||

| BRASS | HPb63, HPb59, H59, H68, H80, H90, ETC. | ||||

1. Low density. The density of aluminum is about 2.7 g/cm3. Its density is only 1/3 that of iron or copper.

2. High plasticity. Aluminum has good ductility and can be made into various products by pressure processing methods such as extrusion and stretching.

3. Corrosion resistance. Aluminum is a highly negatively charged metal, and a protective oxide film will be formed on the surface under natural conditions or anodizing, and it has much better corrosion resistance than steel.

4, easy to strengthen. Pure aluminum is not very strong, but it can be increased by anodizing.

5. Easy surface treatment. Surface treatments can further enhance or alter the surface properties of aluminum. The aluminum anodizing process is quite mature and stable in operation, and has been widely used in the processing of aluminum products.

6. Good conductivity and easy to recycle

Surface treatment of aluminum products

1.Anodizing - Most popular

Anodic oxidation refers to the electrochemical oxidation of metals or alloys. Under the corresponding electrolyte and specific process conditions, aluminum and its alloys form an oxide film on the aluminum product (anode) due to the action of an applied current. Anodizing can not only solve the defects of aluminum surface hardness and wear resistance, but also prolong the service life of aluminum and enhance the aesthetics. It has become an indispensable part of aluminum surface treatment and is currently the most widely used and very successful craft.

2.Sandblasting

The process of cleaning and roughening metal surfaces using the impact of high-speed sand flow.

The surface treatment of aluminum parts in this method can obtain a certain degree of cleanliness and different roughness on the surface of the workpiece, so that the mechanical properties of the surface of the workpiece are improved, thus improving the fatigue resistance of the workpiece and increasing the gap between it and the coating. The adhesion of the coating prolongs the durability of the coating film, and is also conducive to the leveling and decoration of the coating.

3.Polishing

Using mechanical, chemical or electrochemical action to reduce the surface roughness of the workpiece to obtain a bright, flat surface processing method. The polishing process is mainly divided into: mechanical polishing, chemical polishing, electrolytic polishing. After mechanical polishing + electrolytic polishing, the aluminum parts can be close to the mirror effect of stainless steel. This process gives people a sense of high-end simplicity and fashionable future.

4. Wire Drawing

Metal wire drawing is the manufacturing process of repeatedly scraping an aluminum sheet out of lines with sandpaper. Drawing can be divided into straight drawing, random drawing, spiral drawing, thread drawing. The metal wire drawing process can clearly show every tiny silk mark, so that the fine hair luster appears in the metal matte, and the product has a sense of fashion and technology.

5. High gloss cutting

Using the engraving machine, the diamond knife is reinforced on the main shaft of the engraving machine rotating at a high speed (generally 20,000 rpm) to cut the parts, and a local highlight area is generated on the surface of the product. The brightness of the cutting highlights is affected by the speed of the milling drill. The faster the drill speed, the brighter the cutting highlights, and vice versa, the darker and easier to produce cutting lines. High-gloss and high-gloss cutting is particularly used in mobile phones, such as iphone. In recent years, some high-end TV metal frames have adopted high-gloss milling process. In addition, anodizing and wire drawing processes make the TV set full of fashion and technology.

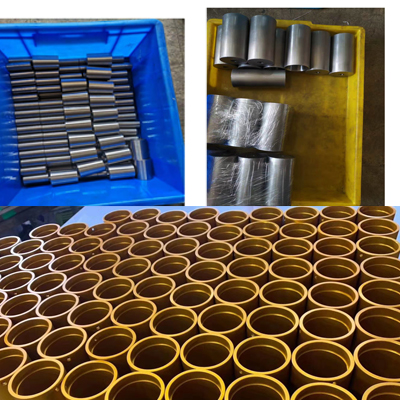

Krosino could supply different kinds of CNC products according to customers' demands , we welcome any client's enquiry along with the specification and requests from all over the world .

aluminum cnc machining service aluminum parts aluminum cnc turning service stainless steel cnc service stainless steel cnc machining service brass cnc turning

|

|

|

| Shock Proof Bubble Film Board | Packing Belt | Plywood Cases |

|

|

OTHER PACKING TYPES COULD BE CUSTOMIZED TOO |

| Plywood Cases | Pallets |

|

|

|