As one of the fastest-growing precision CNC machining services suppliers in China, the following machining capabilities at Krosino are available to serve your needs of CNC machining, from rapid prototyping to precision parts and tooling machining, to end-use production.

CNC Turning: a technology through which the material block fixed on the CNC turning center or lathe rotating with high speed, while the cutting tool moving into the rotating axis to process the workpiece, to get CNC turned parts with accurate sizes.

CNC Milling: generally regarded as the most common machining process, which refers to utilizing a CNC milling cutter to do circular motion and create milled parts with certain shapes and details in a stationary piece, including slots, holes, notches, grooves, etc.

CNC Drilling: a cutting process in which the workpiece is fixed, aligning the cutter center with the hole center and rotate to produce round holes, can be done on lathes and mills.

CNC Milling and Turning: a compound machining technology in which the cutting tool and workpiece are both rotating, to produce complex curved or special-shaped parts through designed multiple kinds of tasks.

Wire EDM: EDM parts from prototypes to full production with tight tolerance and complex construction.

|

1800

Factory Area

|

90~100

Employees

|

US$1500,000+

Annual Revenue

|

100+

Cooperative suppliers

|

OEM

Brands

|

| 3-AXIS MILLING | 4-AXIS MILLING | TURNING | |

| MAX. PART SIZE | • 1500 x 1100 x 500 mm • 59.0 x 43.3 x 19.6 in |

• 1500 x 1100 x 500 mm • 59.0 x 43.3 x 19.6 in |

• Ø 300 x750mm • Ø 11.8 x 29.5 in |

| MIN. FEATURE SIZE | • Ø 0.50 mm • Ø 0.019 in |

• Ø 0.50 mm • Ø 0.019 in |

•Ø 0.50 mm • Ø 0.019 in |

| TOLERANCES | ±0.01 ~ ±0.001mm ,according to customers' requests | ||

| 5-AXIS MILLING | Accept custom made from our partners | ||

When selecting a material, consider the material properties, manufacturability characteristics, cosmetic appearance, and cost.

| TYPE | MATERIAL | FINISH | |||

| ALUMINUM | AL6061,AL6063,AL6082,AL7075,AL5052 ,ETC. | Clear Anodized,Color Anodized,Sandblast ,Chemical Film,Brushing,Polishing,Chorming | |||

| STAINLESS STEEL | 201SS,301SS,303SS,SUS304,316SS ,ETC. | Heat treatment,Polishing,Passivating,Laser engraving,Brushing,Electrophoresis | |||

| STEEL | Steel,carbon steel,4140,4340,20#,45# ,ETC. | Powder Coated,Zinc Plating,Oxide Black,Nickel Plating,Chrome Plating,Heat Treatment | |||

| PLASTIC | ABS,PE,PA,POM,DELRIN,ETC. | White,Black,Blue ,Laser engraving,ETC. | |||

| BRASS | HPb63, HPb59, H59, H68, H80, H90, ETC. | ||||

Surface treatment of stainless steel products

Heat treatment,Polishing,Passivating,Laser engraving,Brushing,Electrophoresis,according to parts request .

Is 304 or 316 easier to machine?

Type 304 is more machinable than 316 stainless steel. Not only is grade 304 steel easier to machine but it is easier to clean. That is one reason why it comes in so many different finishes. That is also why it is used on surfaces that are visible to the public.

How To Choose The Parts Material For CNC Processing ?

CNC machining can create high precision, end-use parts for nearly any application. It allows for amazingly tight tolerances on part dimensions and complex designs. But like any manufacturing process, the material selection is a critical component in determining the overall functionality and cost of your part: the designer defines the important material characteristics to the design—hardness, rigidity, chemical resistance, heat treatability, and thermal stability to name a few.

Metals

As a general rule, softer metals, like aluminum and brass, as well as plastics machine easily and will take less time to remove material from the part blank which in turn reduces machine time and cost of machining. Harder materials, like stainless steel and carbon steel, must be machined with slower spindle RPMs and machine feed rates which would increase the cycle times versus the softer materials. As a general rule, aluminum will machine about 4 times faster than carbon steel, and stainless steel will machine half as fast as carbon steel.

The type of metal is a critical driver in determining the overall cost of the part. For example, 6061 aluminum bar stock is approximately half the price per pound of aluminum plate, and 7075 aluminum bar stock can be 2 to 3 times the cost of 6061 bar stock. 304 stainless steel costs about 2 to 3 times what 6061 aluminum costs and is about twice as much as 1018 carbon steel. Depending on the size and geometry of the part, the material cost can be a significant portion of the overall price of the part. If the design does not warrant the properties of carbon or stainless steel, consider using 6061 aluminum to minimize the material cost.

Plastics

Plastic material can be a less expensive alternative to metals if the design does not require the rigidity of metal. Polyethylene is easy to machine, and it is about 1/3 the cost of 6061 aluminum. ABS is typically 1.5 times the cost of acetal. Nylon and polycarbonate are approximately 3 times the cost of acetal. Although plastics could be a cost-effective material alternative, keep in mind that depending on the geometry, tight tolerances can be harder to achieve with plastics, and parts can warp post-machining because of the stress created when material is removed.

Here are a few additional guidelines to consider for choosing the metal or plastic that's right for your part:

What will your part be used for?

The end environment where your CNC machined part will be used will have the most significant impact on material selection. For example, if you’re using your part outside or in wet environments, use stainless steel as opposed to carbon steel so your part won’t rust.

Design specifications like stress load, tolerance, and types of fastening (welding, rivets) can also impact your choice of material, as can specifications such as for military and aerospace parts or FDA-regulated environments.

Does weight matter?

In general, standard aluminum alloys like 6061 are great, low-density options to keep weight down if a metal is required. Plastics like Delrin and ABS can help keep the weight down even more if tradeoffs in strength can be made.

Strength and heat resistance

There are many different ways to measure material strength including tensile strength, material hardness, and wear resistance. Choosing the material that incorporates the different types of strength your design calls for will allow you to select the best material for your part.

Likewise, very low or very high temperatures will restrict you from using certain materials. Environments where there is high temperature fluctuation are particularly important to consider since some materials will expand or contract considerably even with small temperature changes.

Pricing

The manufacturability and overall cost of your project will influence your choice of material. In general, the more material your part uses, the more expensive it will be. Likewise, specialty materials and extremely strong materials, like titanium, will also cost more.

Krosino could supply different kinds of CNC products according to customers' demands , we welcome any client's enquiry along with the specification and requests from all over the world .

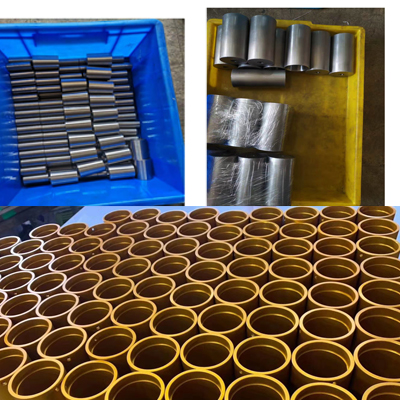

stainless steel cnc machining service stainless steel parts stainless steel cnc turning service stainless steel cnc service stainless steel cnc machining service

|

|

|

| Shock Proof Bubble Film Board | Packing Belt | Plywood Cases |

|

|

|

| Plywood Cases | Pallets | Loading Container |

|

|

|